News Article List

New Machining Center

2023/3/10

2023/3/10

We have installed a new machining center.

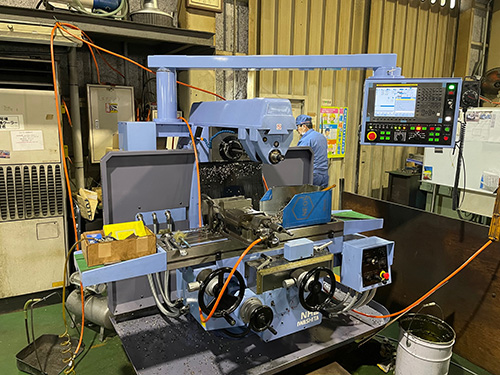

New Milling Machine

2022/12/1

2022/12/1

We have installed a new milling machine.

New Robot

2022/03/20

2022/03/20

We have installed a new robot for processing machines.

New Robot

2022/02/20

2022/02/20

We have installed a new robot for processing machines.

New Processing Machines

2021/12/09

We have installed two new processing machines.

DMG MORI CNC Turning Center NLX2500/700 milling specification.

DMG MORI CNC Turning Center NLX2500/500 2-axis turning specification.