Why KVB’s Implant?

The Reason Why We Will be Chosen

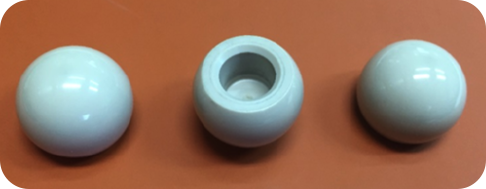

Concretely speaking, that is because of the parts of hip prosthesis we make;“Femoral Head Ball”, “Outer Cup” and “Bipolar Cup”.We manufacture infinitely perfect sphere of which sphericity accuracy is from 0.1μ to 0.3μ. The sphere surface is infinitely polished and their surface roughness is less than Ra0.03μ. Each parts of prosthesis need to bear smoothly when legs move, and the axis of the bearing surface will be the femoral head ball. The high accuracy of the femoral head ball contributes to the longevity of the hip replacement system. KVB has the top share domestically in Japan in the area of the ball for the stainless ball valve. Accumulated spherical machining technology starting from 1964 is leveraged for the implant parts spherical machining.

-

- Femoral Head

-

Availabe Sizes Φ22、Φ26、Φ28、Φ32、Φ36Please contact us for other sizes. High Precision Product Specifications ・Sphericity accuracy from 0.1μ to 0.3μ.・Surface roughness less than Ra0.02μ. Available Materials CoCrMo, Ceramic, Peek ResinPlease contact us for other materials.

PEEK Resin Femoral Head -

- Outer Cup

-

Available Sizes Φ32、Φ33、Φ34、Φ35、Φ36、Φ37、Φ38、Φ39、Φ40、Φ41、Φ42、Φ43、Φ44、Φ45、Φ46、Φ47、Φ48、Φ49、Φ50、Φ51、Φ52Please contact us for other sizes. High Precision Product Specifications ・Sphericity accuracy from 0.1μ to 0.3μ・Surface roughness less than Ra0.02μ.

Machining Process

NC Lathe or Combined NC Lathe

Even during the process of cutting blanking, continuous machining of high precision sphere of spherical accuracy of less than 5μm is possible.

Spherical Surface Polishing(Rough Polishing→Semi-Finishing→Finishing→Super-Finishing)

We perform from rough polishing to four precision polishing stages, using our original spherical polishing machine.We have developed our original grindstones (diamond, CBN, GC, WA).Quality Control Process

Under strict quality control, we deliver quality-guaranteed products utilizing various precision measuring instruments including high precision roundness measuring instruments to customers.

【Tokyo precision roundness measuring instrument RONCOM 55A】

We guarantee the industry’s top-class rotation accuracy of 0.02 μm. A high-rigidity rotary table compatible with large-sized workpieces is used, and high-speed alignment realizes high-efficiency automatic measurement.

We guarantee the industry’s top-class rotation accuracy of 0.02 μm. A high-rigidity rotary table compatible with large-sized workpieces is used, and high-speed alignment realizes high-efficiency automatic measurement.

【Mitsutoyo three-dimensional measuring device CRYSTA-APEX S544】

The power of the first term 1.7μm. This is a high precision true circle CNC degree measuring instrument that guarantees the maximum tolerance length measurement error Eo, mpe = (1.7 + 3 L / 1000). Temperature correction system equipped with a temperature correction system that can guarantee the accuracy of the measuring instrument under an environment of 16 to 26 ° C.

The power of the first term 1.7μm. This is a high precision true circle CNC degree measuring instrument that guarantees the maximum tolerance length measurement error Eo, mpe = (1.7 + 3 L / 1000). Temperature correction system equipped with a temperature correction system that can guarantee the accuracy of the measuring instrument under an environment of 16 to 26 ° C.

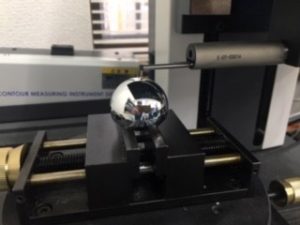

【Tokyo Precision surface roughness / contour surface measuring instrument SURFCOM 1900 SD-12】

This model is the first in the world to adopt a linear motor drive for surface roughness and contour shape measurement machines. Non-contact drive and simple structure achieves the world’s highest level of low vibration and high-speed drive. It is possible to maintain high precision measurement for a long time.

This model is the first in the world to adopt a linear motor drive for surface roughness and contour shape measurement machines. Non-contact drive and simple structure achieves the world’s highest level of low vibration and high-speed drive. It is possible to maintain high precision measurement for a long time.

【Keyence Laser Microscope VK-X250】

It can measure and analyze a wide range of fine shapes. It can measure and analyze 50 mm to 1 nm with high accuracy. Non-contact, ultra-high-precision measurement analysis is possible on the surface roughness that can be read by high-precision linear scale. Observation power: This machine covers an area of 28,800 times from a 35x optical microscope to an SEM. Measuring power: Measure at an instant with a non-contact laser at the nano level without damaging the measured object. Analysis power: Quantify the minute shape, analyze the differences between the surfaces you want to know, such as multiple sample evaluation and ultra-fine analysis, at the nano level.

It can measure and analyze a wide range of fine shapes. It can measure and analyze 50 mm to 1 nm with high accuracy. Non-contact, ultra-high-precision measurement analysis is possible on the surface roughness that can be read by high-precision linear scale. Observation power: This machine covers an area of 28,800 times from a 35x optical microscope to an SEM. Measuring power: Measure at an instant with a non-contact laser at the nano level without damaging the measured object. Analysis power: Quantify the minute shape, analyze the differences between the surfaces you want to know, such as multiple sample evaluation and ultra-fine analysis, at the nano level.